Introduction

When it comes to martensitic stainless steel, the 420 grade is a notable mention known for its hardness and corrosion resistance. This grade gets its hardness from heat treatment processes such as quenching.

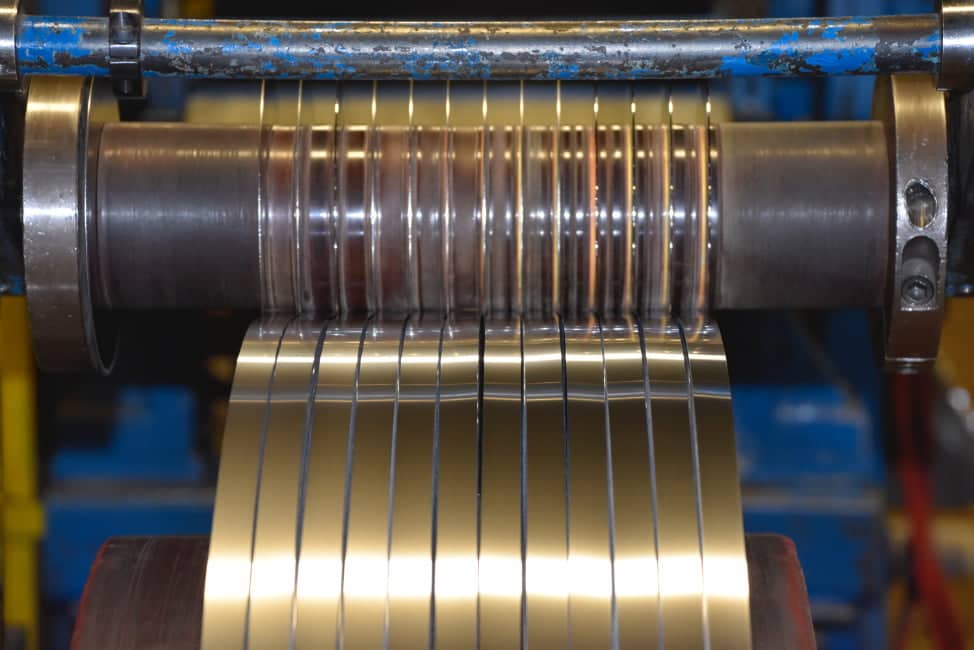

Within this family, 420J1 and 420J2 are two prominent grades that achieve their hardness through high-temperature heating followed by quenching in oil or open air. The level of carbon present largely determines the maximum hardness these steels can achieve upon being quenched.

420J1 stainless steel and 420J2 stainless steel are acclaimed for their hardness coupled with excellent resistance to corrosion. 420J2 tends to be harder than 420J1 due to a higher concentration of carbon. The quenching process for these steels is recommended at temperatures ranging from 980-1050℃, and both grades exhibit magnetic properties.

Post heat treatment, 420 stainless steel typically reaches a hardness around HRC52-55. This level of hardness provides adequate performance against damage, which makes these steels a preferred choice for manufacturing knives, thanks to their ease of cutting and polishing capabilities.

Join us as we delve deeper into the world of 420J1 and 420J2 stainless steel and explore what sets them apart.