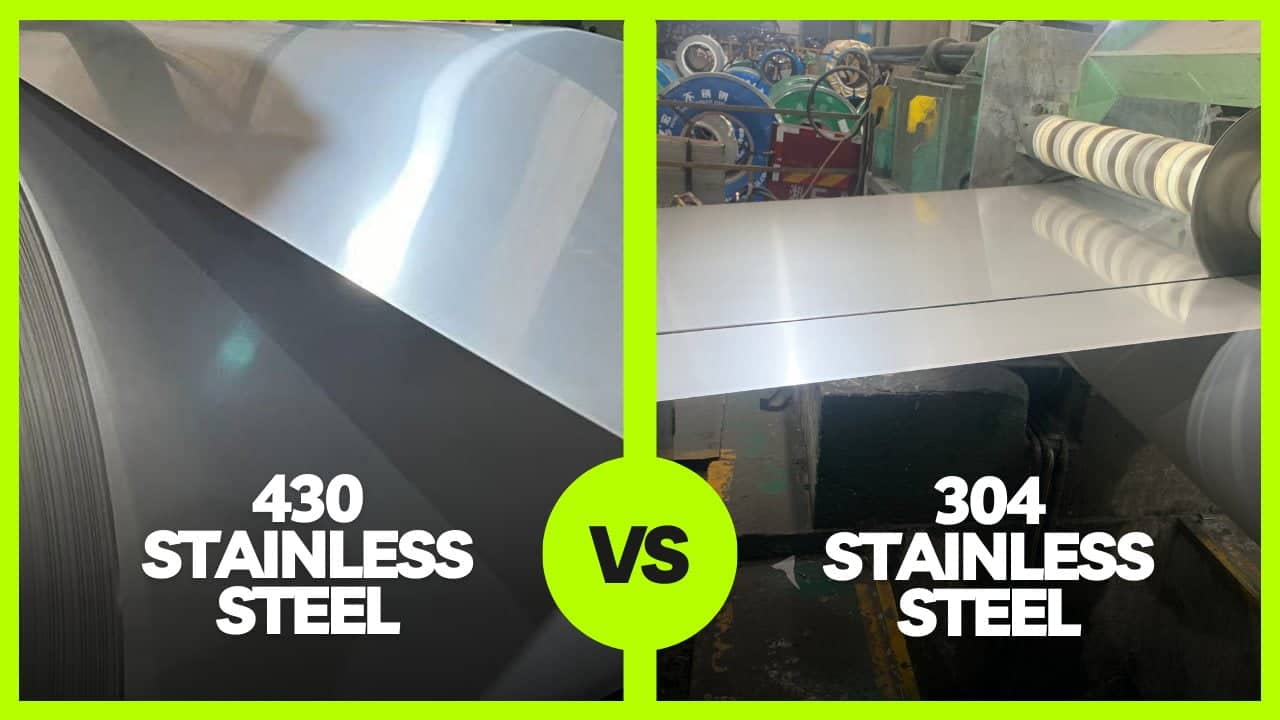

Introduction

Stainless steel is a versatile and essential material widely used in various industries due to its exceptional resistance to corrosion, strength, and aesthetic appeal. Among the many types of stainless steel, 430 and 304 are two commonly used grades, each offering distinct properties that make them suitable for different applications. This blog aims to provide a comprehensive comparison between 430 and 304 stainless steel, focusing on their composition, performance, applications, and cost considerations. Understanding these differences will help in making informed decisions when selecting the appropriate stainless steel for specific needs.