What's the difference between 201 J1, J2, J3, J4, J5?

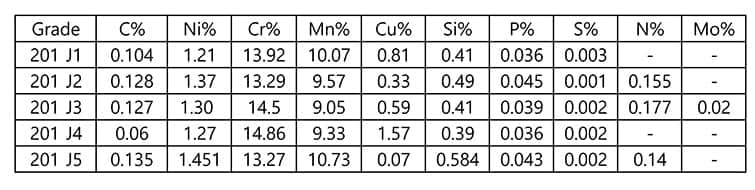

In the realm of stainless steel, the stainless steel 201 grade might appear homogenous at first glance, but did your supplier ever explain the differences between the J1, J2, J3, J4, and J5 variants to you? These classifications are well known among industry insiders in the stainless steel market. However, customers may not fully grasp the unique characteristics of these steel types. Despite all being classified under the 201 material#, why are there so many variants, and why do their prices vary? Today, let us demystify some of the nuances of 201 stainless steel for you.